Household waste overview

Household waste overview

(Written/updated 1/03/17)

Those implementing government strategy for dealing with household waste must recognise 1) the low market value of any recyclables obtained, 2) the high cost of UK labour dealing with this waste relative to the value of the material reclaimed and 3) the resistance by packaging manufacturers and goods retailers to countenance any reduction in use of disposable packaging, other than a little light-weighting.

Until the introduction of the landfill tax in 1996 by the UK government, designed to reduce the production of the greenhouse gas methane emitted from buried putrescible waste, household waste was largely landfilled. With this tax now increased to £82.60 per tonne, councils, in order to reduce the cost of landfilling and achieve government recycling targets, have set up systems of collection for household waste to compost and recycle this waste and so divert it away from landfill.

Ways for dealing with household waste

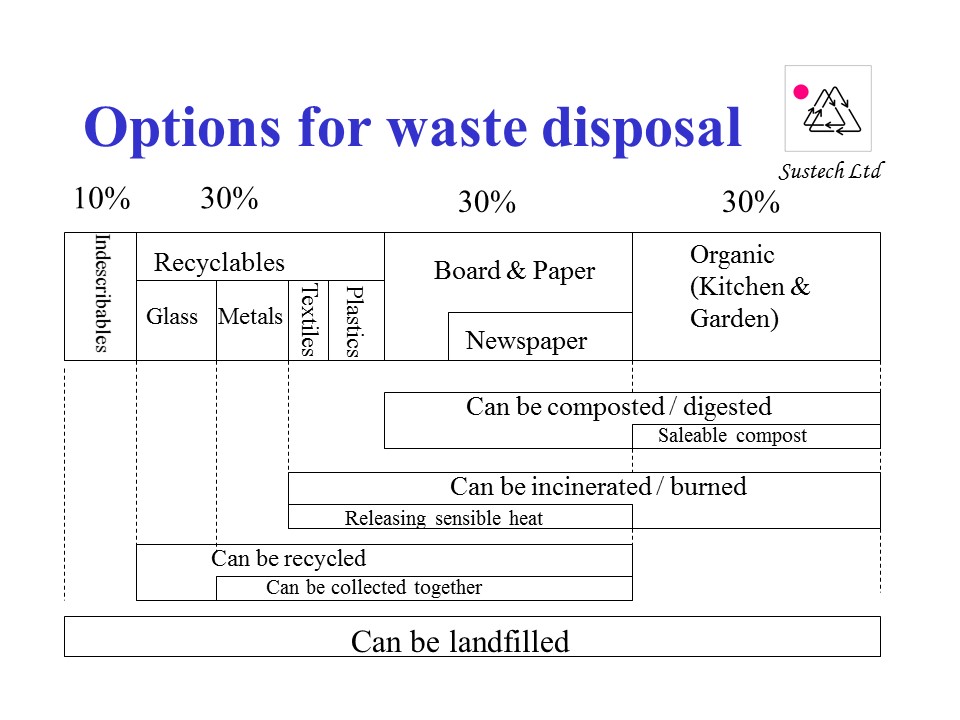

Household waste can be dealt with in a number of ways, as shown in the diagram opposite, although govern ment directives no longer allow some of the practices.

ment directives no longer allow some of the practices.

Items like glass, plastic bottles, aluminium, steel, paper and wood are relatively easy to recycle, while plastic films are not. All organic wastes other than plastics can be composted or anaerobically digested. Plastics and wood can be burnt.

Zero Waste Scotland, the Scottish Government department that is responsible for Scotland’s waste policy, has objectives to 1) ban the landfilling of all municipal biodegradable wastes by 2020, 2) ban the landfilling or burning of potential recyclables, 3) achieve a recycling rate of 70 % by 2025, and 4) standardise on a three stream recycling system, these being a) glass bottles, b) paper and card and c) plastic bottles and cans.. The consequence of these objectives, if local authorities obey these dictates, is that the landfilling of waste will soon no longer be an option.

What does recycling involve?

While recycling of waste appears sensible, it involves a long sequence of actions. First recyclables are collected from homes, segregated either at the kerbside into different containers in a refuse collection vehicle (RCV), or transported in a single compartment vehicle to a municipal reclamation facility (MRF, pronounced murf), for separation. The separated materials are then put over moving conveyor picking tables, where contaminants are mechanically and manually removed. With steel and aluminium containers, magnetic devices are used to remove these from plastics and glass. For separation of plastics into their different polymers, essential for further reprocessing as they all have different melting points, sophisticated near infrared reflectance (NIR) scanners are used. The different fractions of metals and polymers are diverted to baling machines, which compress the materials ready for transport.

Recyclables shipped east

The highest prices for the bales tends to be paid by agents acting for reprocessors having the lowest labour costs, and possibly the lowest environmental standards, usually located in China and the Far East. This results in much paper and most plastics being packed into containers, and shipped east. There the paper is further separated, cleaned of contaminants and made into new paper, while the plastics are similarly decontaminated, granulated, washed, float separated, dried, heated to become liquid and then extruded to form pellets suitable for making into new plastic products. These plastic pellets will obviously not be of the same quality as that from virgin plastic pellets, so there is an element of “down cycling”, in the end product. Recycling therefore often results in a 13,000 mile journey for materials ultimately being sold as low quality plastic feedstock.

What should government strategy be?

Many see the solution to avoid the export of waste plastics for reprocessing, is for the UK government to part fund machinery for use in the UK plastics recycling industry, so that it gets established and becomes competitive with recycling in the Far East. However the East’s low cost labour will always give them a comparative advantage.

Reviewing waste treatment practice

Another approach to capital subsidies for recycling businesses is to take a step back and re-evaluate the whole issue of packaging and recycling, specifically the troublesome area of plastic packaging. This would entail manufacturers and retailers taking real responsibility for what happens to packaging at the end of use. For this to happen packaging items would be clearly marked for 1) Returnable / reuseable, 2) Recyclable, 3) Compostable or 4) Burnable. Vague terms like “May be recycled”, would not be allowed. The post use treatment would therefore be as below:-

- Returnable / Re-useable : – Container bearing a deposit returned to supermarket by householder next time they shop → Back load to distribution centre → back load to supplier→ washing prior to refilling or sent to a reprocessor for shredding or melting

- Recyclable : – Collected by council → kerbside segregated/MRF → separated → contaminants removed → baled → container lorry to docks → loaded onto ship → 13,000 mile voyage to China → lorry to factory → contaminate removal → shredding → washing → drying → heating → pellet manufacture → melt → extrude into new product

- Compostable packaging: – Placed in kitchen caddy for composting or Anaerobic digestion (AD)

- Burnable: – Put burnable waste in residual waste wheelie bin→ Collected by council → Separated from other residuals → made into residue derived fuel bales → shipped to energy from waste (Efw) plant in UK or Europe → Burnt to produce energy

Assessment of above waste treatment options

In terms of simplicity, and the minimisation of labour and transport costs, options 1 and 3 win easily.

Returnable / Re-useable : –. A requirement for containers to bear a deposit is mandatory in eleven states in the US, which have introduced “bottle bills”. Not only has this measure massively improved return and recycling rates, to 90% (compared to the UK’s 25% for plastic bottles in 2012) but it reduces litter composed of 40% drinks containers to 6% and provides income for poor people who collect discarded containers. Introducing bottle bills in the USA, however, involved a huge battle with drinks manufacturers. Companies in the UK have not had this imposed on them yet. Our councils bear the main cost of collecting and dealing with one-use containers following disposal, with manufacturers and retailers paying only a proportion via packaging recovery notes (PRNs).

Compostable packaging: – Whatever manufacturer’s state on their packaging about material being “not currently recyclable” or “check local recycling”, flimsy plastic bags, cling film, polythene bags, crisp packets, clear polystyrene boxes, hardware packs with polystyrene display windows are unlikely ever to be recycled in practice. Biodegradable packaging, including see-through film, is readily available either as paper bags or plastic films made from corn or potatoes and could be required by government to be used for all situations where packaging is unlikely to be reprocessed. There would be two types of plastic containers and packaging, 1) truly potentially recyclable, like milk bottles, and 2) biodegradable for films and display packaging. Biodegradable packaging could be phased in over three years, so that when it was allowed to be disposed of into composting collections, all flimsy plastics would be biodegradable. This would prevent non-biodegradable plastics, which can can clog up composting systems to be kept out of compost collections. Nappies made of biodegradable materials would be included in this category of waste. Established companies making oil based plastics will vehemently oppose such a measure, but they should heed warnings from previous industries which have refused to modernise, like Kodak, Nokia and possibly now the oil and gas energy industries. Now is the time to evolve some of their plastic production to eco-friendly products.

Why moving to biodegradable packing is so attractive is that it fits in with nature’s natural cycles. All organic materials, apart from oil based plastics, are biodegradable. A paper bag in contact with soil will disappear in weeks. Wood will crumble to compost in a few years. Plastic will still be present in 50-100 years. It is polluting the seas, in massive mile-wide floating plastic gyres, and turns our road verges into litter strewn eyesores. It blocks culverts in high rainfall countries and kills marine animals, birds and livestock when they ingest it. The higher cost of biodegradable plastics compared to oil based plastics is likely to fall as production volumes increase.

Recyclable : – This option would only be used for plastics and paper suitable for reprocessing, such as PET, HDPE and clean paper and cardboard. The greater the reuse of bottles, the less need for reprocessing.

Burnable: – While there will always need to be an option to burn certain items of household waste like shoes and items made from mixed materials, to avoid sending this material to landfill, it has a number of limitations. New UK regulation requires burnable waste to be separated after collection from residual waste and bans the burning of recyclables. This separation process, while sensible, adds an extra cost to the previous practice of burning unseparated municipal waste.

Oil based plastics require 108 MJ/ kg of energy to manufacture them, but only provide 45MJ/kg when burnt (MacKay, DJC, 2009). Manufacturing packaging to use once, then to burn it for energy, is therefore not as smart as most people think.

Dioxins and furans are produced when burning materials which have a chlorine or fluorine element in them, like salt in food waste and poly vinyl chloride (PVC) plastics and in RTFE plastics. Dioxins should soon be less of a problem as food wastes are to be kept out of Efw plants. These Efw plants use hydrocarbon fuel at boiler start-up and other times when combustion temperatures drop, to ensure the combustion temperatures are kept above 1000 °C, which prevents dioxin or furan production. The flue gas filtration material, which contain toxic dioxins, is sent to concrete lined hazardous landfill for safe storage.

Exhaust gasses from the chimney of the Efw plant contain nitric oxides, hydrogen chloride and sulphur oxides, which when combined with the moisture in the exhaust gas forms concentrated nitric, hydrochloric and sulphuric acids, all being at a temperature of over 1000 °C. These are extremely corrosive to the filtration equipment, which in consequence needs regular maintenance. The filters in modern Efw plants make up half the size of the plant and, while they use fabric and electroscopic filters to trap dust particles, the main filter materials are large quantities of lime and activated carbon, which are subsequently transported to hazardous landfill.

Large Efw plants in Europe are now struggling to find material to burn, so are happy to take baled burnable refuse derived fuel (RDF) waste from Aberdeen to keep their plants viable. There is therefore the danger of UK plants becoming “stranded assets”, with throughputs reducing through waste minimisation and recycling, leading to income from burnt waste decreasing, while plant depreciation and operating costs remain costant. The UK government is trying to limit the construction of more Efw plants, saying that we have enough capacity. Waste companies would like to build more as they say more are needed.

Composting or anaerobic treatment plants are, in contrast to Efw plants, usually smaller in size and are relatively benign treatment systems, reaching maximum temperatures of only 37° C in AD plants and 70 °C in composting installations. The problems of dioxins, very hot corrosive acids, and large sophisticated and expensive plant associated with Efw plants are therefore avoided.

Aberdeenshire and Aberdeen local waste policies

In contrast to Scottish government’s preferred three stream recycling system of collection, Aberdeenshire has chosen a single stream, co-mingled collection system, using one bin. They exclude glass bottles in their collections to prevent the paper and card being contaminated with glass grit. Aberdeen city is moving away from a two stream system of a) paper and cardboard and b) bottles and cans, to a similar single stream system, but with glass bottles included. A MRF is being built in Alten’s Industrial estate, Aberdeen to separate this single stream. A large Efw plant is to be built in Alten’s, Aberdeen, to burn the city, the shire and Moray’s waste. There therefore appears a disconnect between government and local authority policies.

No test data as to the amount of glass contamination in the paper or plastic has been carried out in a MRF similar to that being built, but the council is confident that the quality of the recyclate will be of good quality and will sell well. While the council’s main priority is to extend recycling to flats and tenements as well as the leafy suburbs and to reduce landfill, the strategy represents a failure mainly by central government to introduce deposits on bottles, to legislate for commercial companies to reduce their packaging and replace oil based plastic packaging with compostible substitutes. Burning waste should be the option of last resort.

An alternative strategy to the EFW plant for Aberdeen and Aberdeenshire

Energy from residual waste is second from bottom in the waste hierarchy (Scottish Government, 2011). However, as Aberdeen City and other authorities have so far failed to drive up their recycling figures, they are faced with a residual waste problem. Increasing landfill costs and government imposed restrictions on how much waste can go to landfill have tempted local authorities to look for easy, albeit expensive, ways to address this matter. The proposed Aberdeen energy-from-waste (EFW) plant is an interim measure to cope with unrecycled residual waste that is predicted to decline in volume over the next decade as reuse, recycling and composting diverts combustible waste from the EFW input waste stream.

Refuse derived fuel (RDF)

Refuse Derived Fuel is the residual waste after non-combustible materials, (e.g. glass, stone, metals) have been removed. The fuel is then usually baled for onward transportation to distant EFW plants. The new Materials Reclamation Facility (MRF) in the Altens Industrial Estate has a production line to produce this material. The present gate fees per tonne for an EFW plant lies between £70-105 per tonne, while that for RDF is £80-90 (Letsrecycle, 2017). The cost of removing the non-combustibles in the RDF adds £10-18 per tonne to this process, giving a combined gate fee and processing cost of £90-123. Potential markets for RDF abroad are the Netherlands, Germany and Sweden, which are currently seeking RDF waste to keep their EFW plants working and financially viable. There is also potential to send RDF to the increasing number of EFW plants in the UK. The benefit from the RDF route is that it uses existing spare EFW capacity in Europe and the UK to allow the changes in local authority waste management practices to be established to a point where future investments in EFW plants, Anaerobic Digesters, composters, etc., can be made with more confidence than at present. An EFW plant is a massive capital investment, with a life of 25 years. Fixed costs dominate its operating costs, so that if the plant operates at less than full capacity, its operating costs may escalate until the plant becomes financially unviable. Aberdeen was the last city in the UK to build high rise flats; we don’t want it to be the last to build an EFW. Some of the uncertainties are dealt with below.

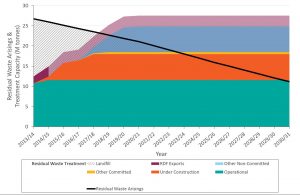

EFW over capacity

Potential EFW capacity in the UK is shown below (Eunomia, 2014).  Where the black line crosses the top purple area, capacity is in excess of that required. This will occur about 2018/19, prior to the Aberdeen facility coming on stream. The Eunomia authors do not know what will happen after this date. They suggest that older EFW plants may have to shut down. Others may go out of business. Alternatively, EFW operators may instead drop their gate fees to keep going, which will benefit RDF producers like Aberdeen, if we decide on this approach. The advantage of sending RDF to the UK and European market for burning, means that shrinking quantities of material for burning will not endanger the viability of an Aberdeen located EFW plant.

Where the black line crosses the top purple area, capacity is in excess of that required. This will occur about 2018/19, prior to the Aberdeen facility coming on stream. The Eunomia authors do not know what will happen after this date. They suggest that older EFW plants may have to shut down. Others may go out of business. Alternatively, EFW operators may instead drop their gate fees to keep going, which will benefit RDF producers like Aberdeen, if we decide on this approach. The advantage of sending RDF to the UK and European market for burning, means that shrinking quantities of material for burning will not endanger the viability of an Aberdeen located EFW plant.

Aberdeen’s recycling policy

To know how well Aberdeen’s new recycling system will work and what proportion of its waste will have to be burnt is as yet unknown. The system needs a couple of years to bed in. Sadly, the system chosen is likely to have serious contamination problems. In the previous kerbside sort system, every council worker (scaffie) was a quality assessor, rejecting non-recyclables, or contaminants when loading the bin lorry. Now that bins in the street have been introduced for flats, flat dwellers may dispose of recyclable material along with their residual waste, and bins specifically for recyclables are contaminated with residual waste. The food waste bins may be contaminated by people passing by, seeing a “rubbish bin” and dumping their drinks bottle or whatever into it. (Look into these bins from time to time to see what we mean). The only differences between the approach to house recycling and flat recycling schemes is that recycling containers for flats need to be smaller, have handles so that they can be carried safely down stairs, and have more frequent collections. This approach would have allowed the kerbside sort system to continue. Aberdeen in future will become known as the Waste Bin City, its streets despoiled with large, old, 1,100 litre bins.

WRAP Welsh recycling evaluation

During the so-called ACC waste consultations, the council’s waste managers promised us that they would to do a trial evaluation of their proposed co-mingled recycling system in a state of the art MRF in England, to ascertain how it performed compared to the present kerbside sort system. This was never done. To decide on a completely new system of recycling for Aberdeen with no testing or trial, not only broke their promise to carry out a trial, but relies completely on assurances from the MRF suppliers that the quality of recyclables will be acceptably high.

In December 2016, WRAP, the Waste and Resources Action Plan, a government body, produced such an evaluation, in their “Harmonised Recycling Collections Costs Project”, for three areas in Wales, an Urban Authority, a Rural Authority and a Valley Authority, which clearly showed that the kerbside sort system gave better value compared to co-mingled, by virtue of the cost of vehicles being lower cost, the higher quality of the recycled material, and the separation of the recyclables being done for no cost by the public (WRAP, 2016). While the original investment was higher for kerbside sort, this was paid back in 18 months and subsequently gave savings of £1m per annum for areas containing 60,000 households.

In a subsidiary part of the study, they found that recyclable material collected separately from glass bottles attracted a £10 per tonne premium. Aberdeen is collecting glass along with the other recyclables, risking contamination and thereby lower material market prices. If recyclable material quality is good, there is usually a market for it. If poor, the market price is either low or non-existent; it is then only fit to be burnt.

The report demonstrated that a good kerbside recycling system offered substantial savings in overall council costs compared to a co-mingled system, the one Aberdeen has just discarded.

Plastic packaging and the circular economy

The huge rafts of floating plastics presently in the sea, plastic gyres, inspired round-the-world yachtswoman Ellen Macarthur to launch the “New Plastics Economy”, where plastic packing never becomes waste. However, while this might seem like wishful thinking, Unilever has announced last week that by 2025, five years after ACC EFW start up, all of its plastic packaging will be fully REUSABLE, RECYCLABLE or COMPOSTABLE. This will probably mean that vegetables for example will be delivered to supermarkets in large reusable plastic trays. Plastic bottles and tubs will be all be one type of plastic, to make reprocessing simpler; and films, sleeves, plastic bags will be compostable, disposed of in the compost bin. This of course may not happen, but Unilever is a large company and this is a very public commitment. Plastics are virtually non-biodegradable, and as such are environmentally unsustainable. To be acceptable in the long term all packaging manufacturers will have to follow the Unilever route.

Since plastics provide the most heat energy of all the waste materials, the calorific value of waste going to EFW plants is going to fall, resulting in less energy generation. Leaving the decision to the next decade to assess whether or not to build an EFW plant would therefore seem a wise decision.

Free energy from the EFW plant

Much has been made of the “free energy” from burning waste for Aberdeen city. Compared to gas fired generating plants, EFW plants are very much more complicated and expensive, as they have to deal with the variations in waste material and gaseous emissions from burning waste. While the addition of a hot water district heating system has been suggested to heat Kincorth and Torry homes, no commitment has yet been made to build this. It will only be built if the large capital investment can be financially justified and this is far from certain. The money would most likely be better spent insulating homes to minimise the energy they presently use.

Decision for Aberdeen City, Shire and Moray

In summary, the three local authorities can either take the risk of building what could become a stranded asset, the nightmare scenario for capital intensive facilities, or delay action for a decade to see how schemes for reuse, recycling, anaerobic digestion and composting increase and improve and how well big business succeeds in removing plastics from the waste stream. In the meantime they would produce RDF for burning elsewhere. To improve the quality in decision making and remove any possible bias from the waste industry for EFW and large capital projects, a consultancy company like Eunomia, should be used to assist decision making.

References for EFW response

| Eunomia, 2014. Residual waste infrastructure review. Issue 7. Pp33. www.eunomia.co.uk |

| Lets recycle, 2017. http://www.letsrecycle.com/news/latest-news/rdf-export-may-become-as-expensive-as-landfill/ |

| Scottish Government, 2011. Zero waste Scotland. http://www.gov.scot/Publications/2011/10/14112444/5 |

| Unilever, 2017. https://www.unilever.com/news/press-releases/2017/Unilever-commits-to-100-percent-recyclable-plastic.html |

| WRAP (2016). Harmonised Recycling Collections Costs Project: Phase One. http://www.wrapcymru.org.uk/sites/files/wrap/Harmonised%20Recycling%20Report%20Nov%202016.pdf |